研究背景

人工智能(AI)和物联网(IoT)与可穿戴电子设备的融合极大地推动了人类通信和生活方式的发展。这些光电双模传感纤维能够感知刺激并将其转换为数字和模拟信号,为智能人机交互界面带来了希望。然而,纤维质量重、伸展性差、缺乏非接触式传感等问题会影响长期舒适性、耐用性和灵敏度,从而阻碍了其在最先进的智能纺织品中的实际应用。

为了满足不同场景下的稳定性、舒适性和灵敏度要求,研究人员提出了一种将摩擦纳米发电机(TENG)和机械发光材料集成到双模电光传感器光纤中的设计方法。碳材料和Ecoflex成为纤维型 TENG 的高效电极对。Ecoflex 以其高性价比、高电负性、独特的可拉伸性(570%)、生物相容性和柔韧性而著称,是负极材料的常见选择。碳材料(如碳纳米管和石墨烯)具有独特的机械和电气特性,如坚固性、热力学稳定性和导电性,是极佳的正极材料。

对于电子光学传感器,先前的研究涉及通过有源矩阵电路将独立的传感和显示元件进行物理组合,这种方法存在各种缺点,包括复杂的电路阻碍了大规模集成。与此相反,利用光子和荧光信号作为直观、高效且接缝较少的信息传递手段已显示出前景。ZnS:Cu 是一种常见的荧光材料,可提供高分辨率的点发光,并增强 Ecoflex 的电负性,从而提高 TENG 的电输出。尽管双模电光传感光纤的设计方法取得了长足进步,但在实现"TENG+ML"结构方面仍然存在挑战,尤其是在材料和结构的优化设计方面。合理的微结构和材料设计对于确保 ML材料不影响传感灵敏度和监测范围至关重要。此外,TENG 和 ML之间必须具备一致的传感响应能力,且无输出延迟。

研究成果

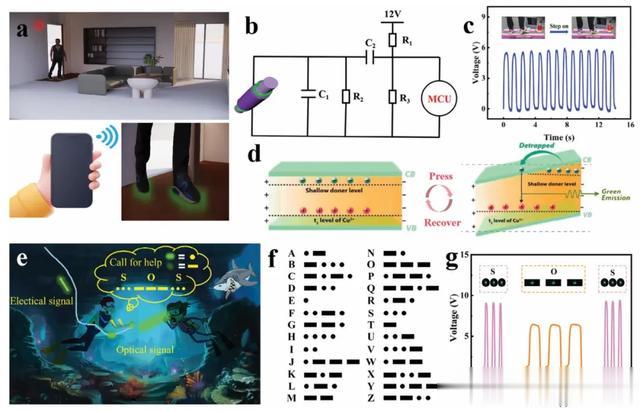

柔性光电双模传感光纤能够感知机械刺激并将其转换为数字-视觉信号,在智能人机交互界面中具有良好的应用前景。然而,沉重的质量、低拉伸性和缺乏非接触传感功能严重阻碍了它们在可穿戴电子设备中的实际应用。为了应对这些挑战,中科院苏州纳米所张其冲研究员团队成功地构建了一种基于轻质碳纳米管纤维的可拉伸自供电机械发光摩擦纳米发电机纤维(MLTENGF)。利用其机械发光三电协同效应,精心设计的 MLTENGF 无论在陆地还是水下都能提供 200% 的出色增强电信号和明显的光信号。MLTENGF 设备具有出色的稳定性,在拉伸200%后灵敏度几乎保持不变。此外,MLTENGF 还具有非凡的非接触传感能力,探测距离可达 35 厘米。作为应用示范,MLTENGF 可用于家庭安全监控、智能古筝、交通车辆防撞和水下通信。因此,这项工作加速了用于智能人机交互界面的可穿戴光电纺织电子产品的开发。相关研究以“Stretchable and Self-Powered Mechanoluminescent Triboelectric Nanogenerator Fibers toward Wearable Amphibious Electro-Optical Sensor Textiles”为题发表在Advanced Science期刊上。

图文导读

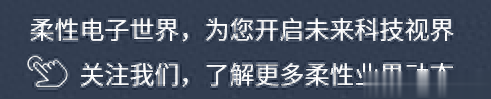

Figure 1. a) Schematic representation of the MLTENGF principle. b) Cross-sectional SEM image of the MLTENGF. c) SEM image showing the surface morphology of ZnS:Cu particles doped in Ecoflex. d)Energy dispersive spectrum of zinc, sulfur, and copper elements. e) Photo of a stretchable MLTENGF, maintaining good performance when stretched to200%strainlevel, alongside its corresponding optical image. f) SEM image of MLTENGF wound into a butterfly-shaped structure (scale: 500 μm). g) Tensile stress–strain behavior at different doping concentrations (0–50%) with an initial length of 300 mm. h) Photo of a flexible MLTENGF, capable of wrapping around a finger and lifting a 100 g weight.

Figure 2. a) Dynamic loading structure schematic for MLTENGF frictional electrical performance. b) Schematic representation of the working principle of the MLTENGF. c) Numerical calculation of the corresponding electric potential distribution using COMSOL software. d) Atomic-scale electron cloud potential well model describing the charge transfer at the copper foil and Ecoflex/ZnS:Cu contact interface. e) Variation in VOC and f) ISC at different doping concentrations (0–50%). The output voltage of the MLTENGF under g) different applied loads and i) different stretch levels. i) Stability test of the MLTENGF under a specific stretch level of 200%.

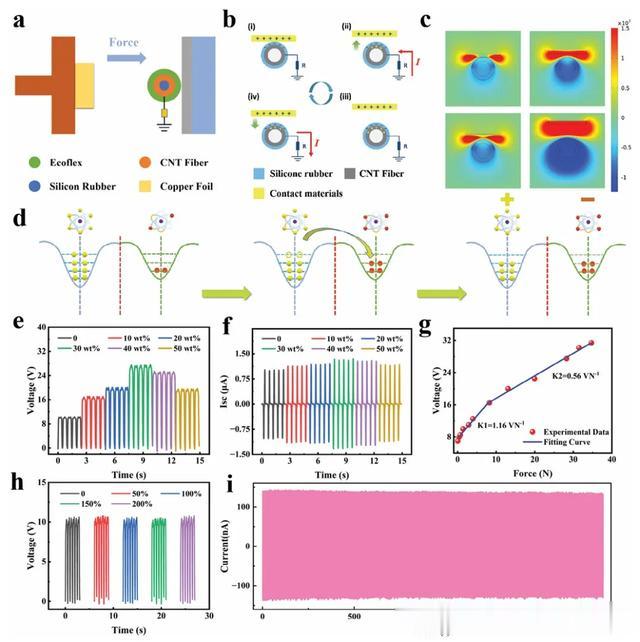

Figure 3. Response of voltage signals to different ranges of motion: a) walking, b) running, and c) jumping. d) Schematic representation of the principle for spatial pressure distribution sensing in TENG under the influence of photoelectric synergy. e) Photo of electronic fabric with a 3 × 3-pixel MLTENGF sensor. f,g) Output voltage (VOC) and luminosity of each pixel MLTENGF sensor array’s pressure distribution when pressing Z31,Z22,andZ13 with f ingers. h) Schematic and equivalent circuit of an “intelligent zither” based on MLTENGF sensors. i) Output signals for five notes (DO, RE, MI, SOL, and LA) and arbitrary note combinations of the “intelligent zither”.

Figure 4. a) Schematic representation of an anti-theft alarm carpet. b) Equivalent circuit diagram of the anti-theft alarm carpet. c) Output signals of the anti-theft alarm carpet in “On–Off” states. d) Schematic energy level diagram for green luminescence in ZnS:Cu under stress. e) Photoelectrically coordinated communication of MLTENGF pressure sensors in an aquatic environment using Morse code. f) Schematic diagram of Morse code principles. g) Transmission of corresponding information underwater by MLTENGF pressure sensors using Morse code.

Figure 5. a) Schematic representation of a non-contact sensing system with Ecoflex/ZnS:Cu as the charge generation layer and CNTF as the charge capture layer. b) Mechanism of non-contact induction in MLTENGF. c) Variations in output voltage and sensitivity with separation distance. d) Output voltages correspond to different distances. e)Non-contact sensing performance of the reported proximity sensor.f)Illustration of MLTENGF applications in pedestrian and vehicle collision avoidance. g,h) Application scenarios of obstacle MLTENGF sensors for avoiding vehicles (rear) and robots (front). i) Schematic representation of non-contact MLTENGF sensors detecting proximity to unknown marine life forms. j)Real-time output signals of non-contact MLTENGF sensors based on the approach and retreat of fish in aquatic environments.

总结与展望

总之,作者构建了一种可拉伸、自供电的双模 MLTENGF,可在接触和非接触模式下实现快速响应传感。新开发的MLTENGF将 CNTF和 Ecoflex/ZnS:Cu 封装材料依次组装在可拉伸的硅泡沫芯材上,在高达 200%的应变下仍能表现出稳定的功能,解决了之前人们对传统电光双模传感光纤质量大、可拉伸性差的担忧。值得注意的是,MLTENGF在非接触式传感方面表现出色,传感距离可达 35 厘米,在实现非接触式人机交互方面取得了进步。已展示的重要应用包括健康监测、压力传感、智能拉链、警报和防撞,这些都体现了智能光纤电子技术的巨大优越性。此外,MLTENGF 独特的水下传感、救援应用和专门的摩尔斯电码光电协同技术也展示了其在解决不可感知性、促进信息交流和支持救援行动方面的多功能性。从本质上讲,MLTENGF 是TENG 和 ML 材料集成的发展产物。它的特点和多样化应用克服了当前多模纺织电子产品的局限性,为未来智能人机交互界面的发展提供了可能。

文献链接

Stretchable and Self-Powered Mechanoluminescent Triboelectric Nanogenerator Fibers toward Wearable Amphibious Electro-Optical Sensor Textiles

https://doi.org/10.1002/advs.202401109

来源:i学术i科研