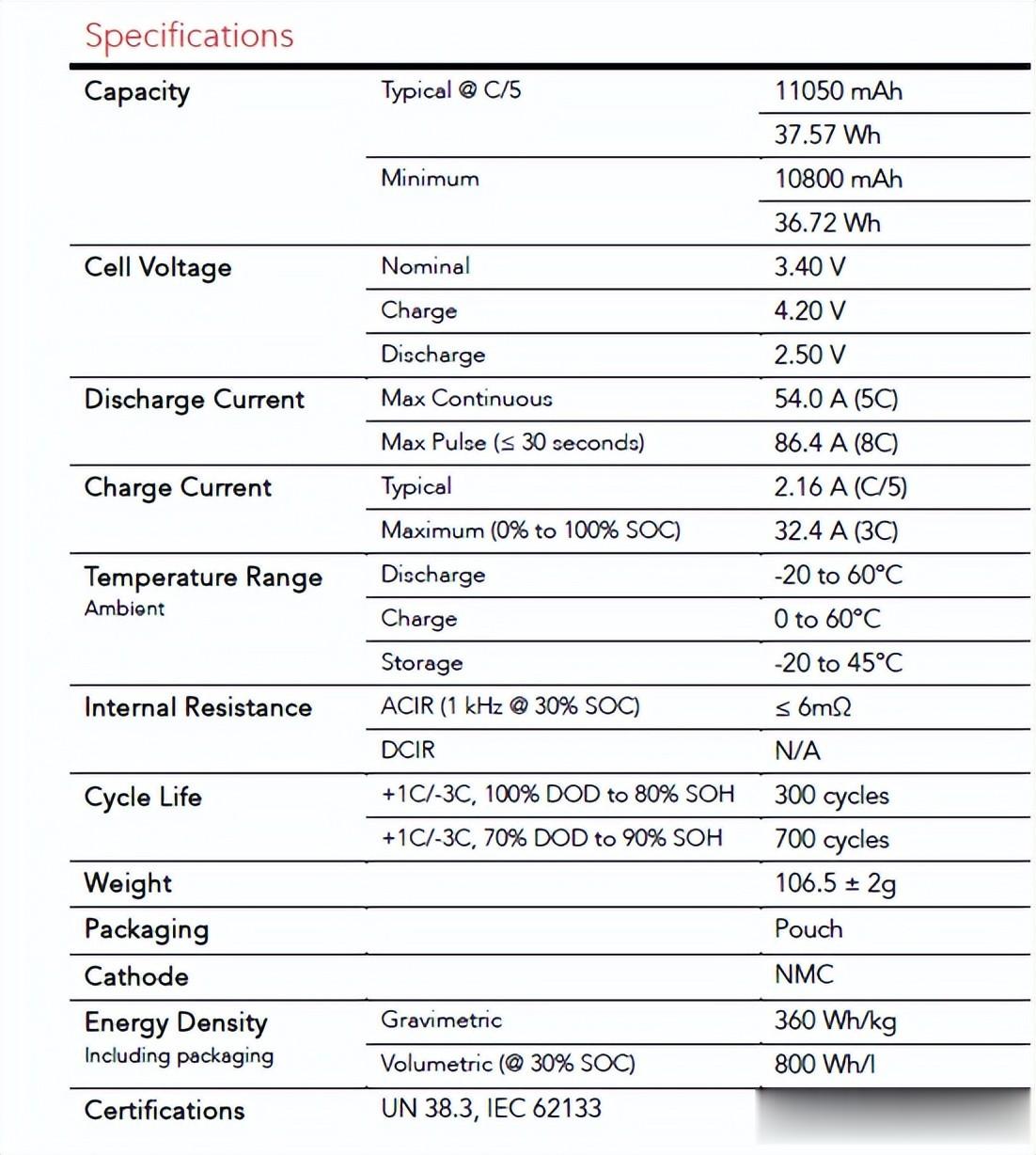

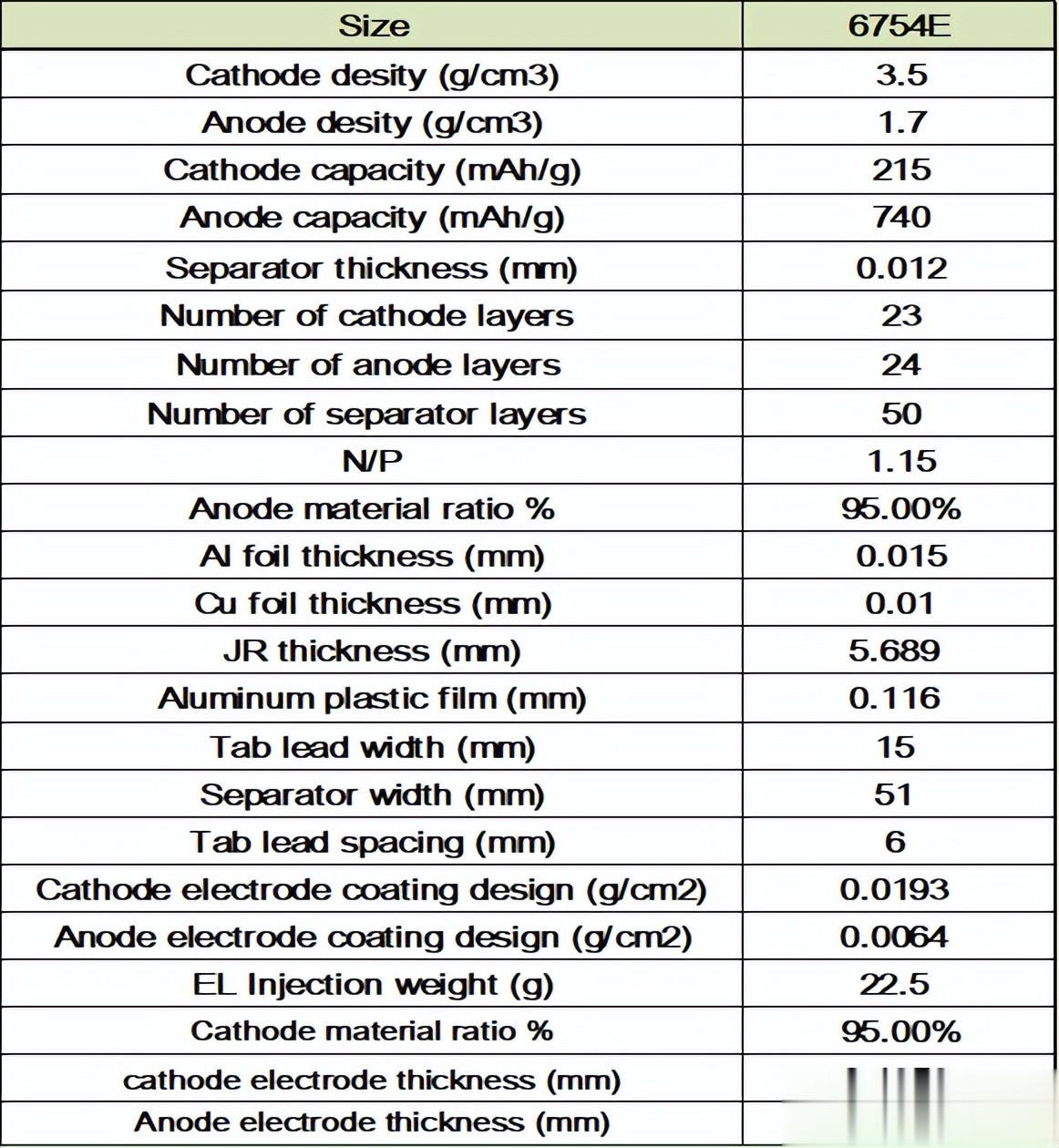

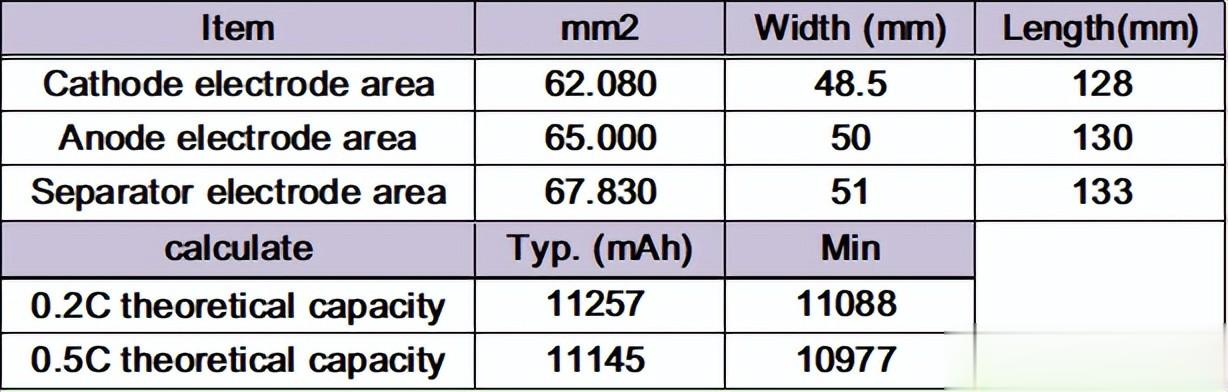

Specifications

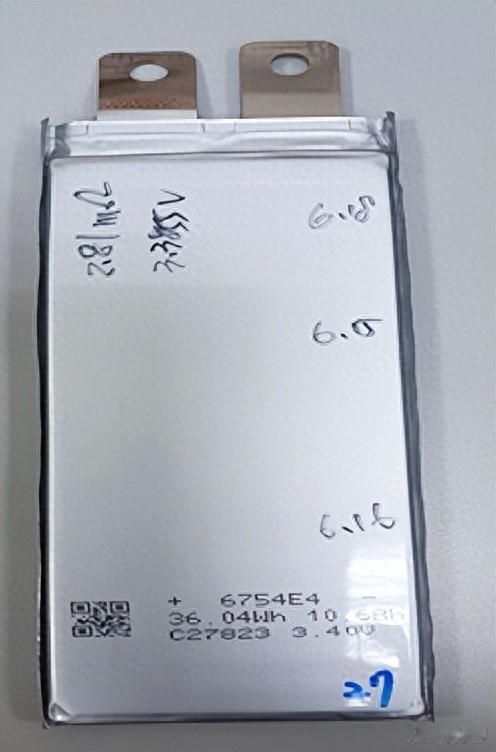

Actual test:

●Temperature: 20℃±5 ℃, Humidity: ≤ 75%RH

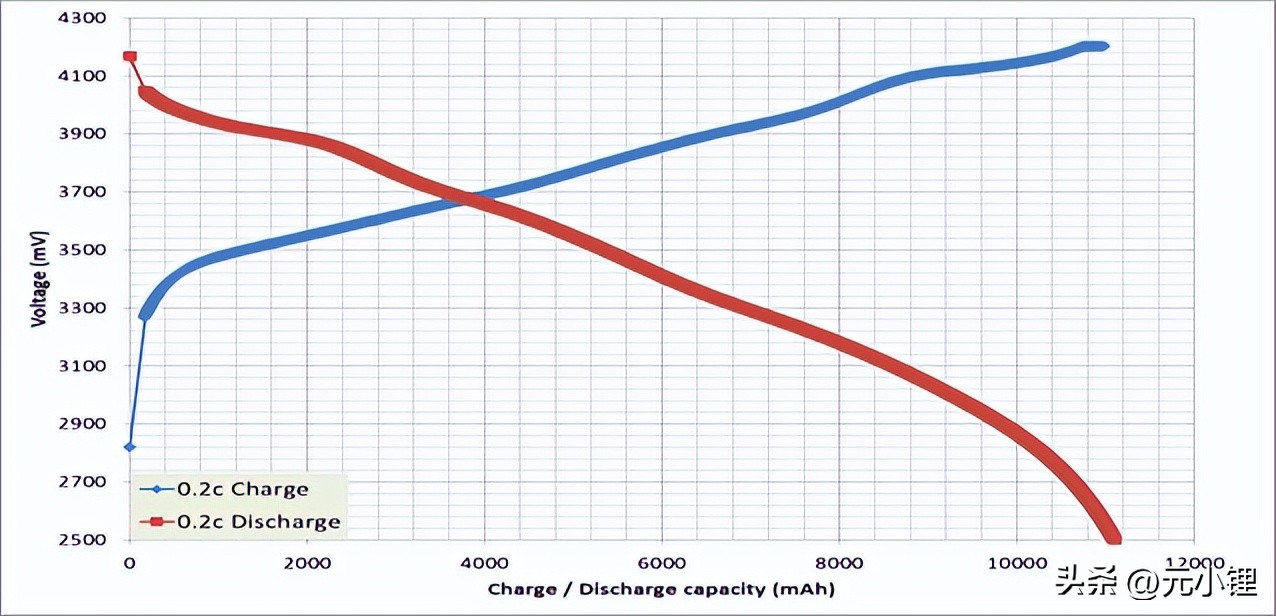

●0.2C charge to 4.2V, then CV(constant voltage 4.2V) charge till current 0.05C.

●Rest for 10 min

●Discharge method : Discharge the cell to 2.5V with 0.2C.

The measured 0.2C capacity is 11099mAh

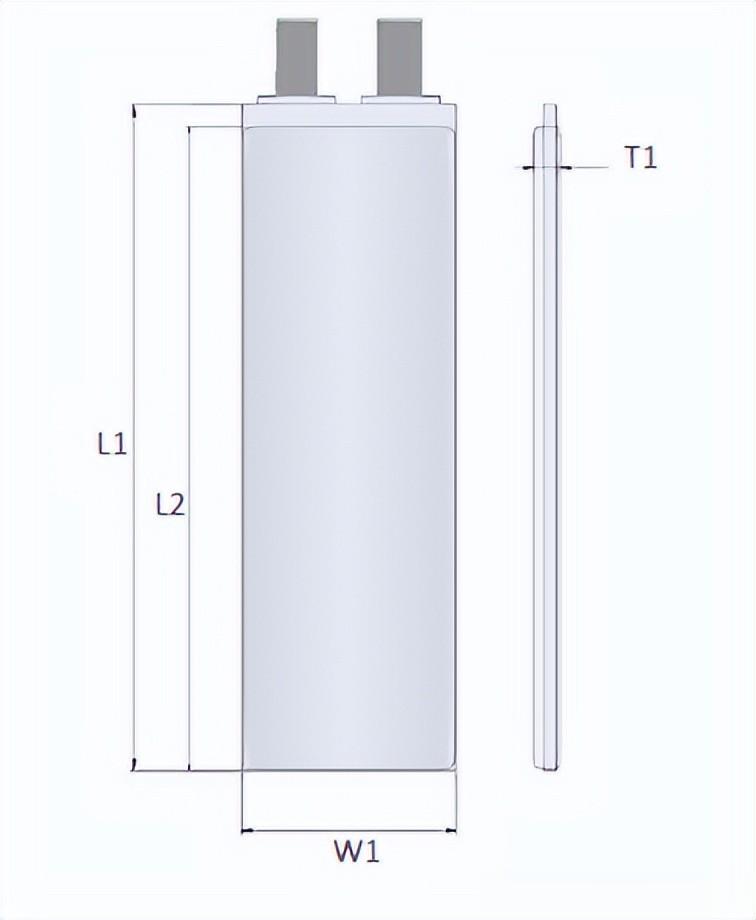

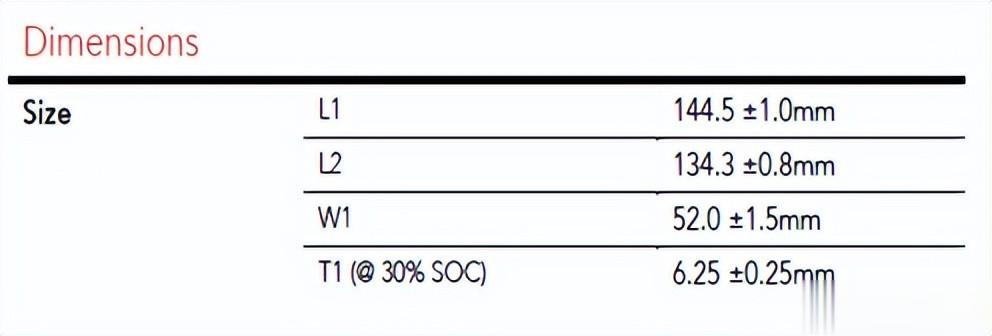

uCell size

Actual measurement:

Item

50%SOC

100%SOC

Increase%

IR (mΩ)

2.81

3.459

23.1%

OCV (V)

3.3855

4.1242

*

T1 (mm)

6.18

7.07

14.4%

T2 (mm)

6.15

7.03

14.3%

T3 (mm)

6.16

7.15

16.1%

W (mm)

52.07

*

*

L (mm)

145

*

*

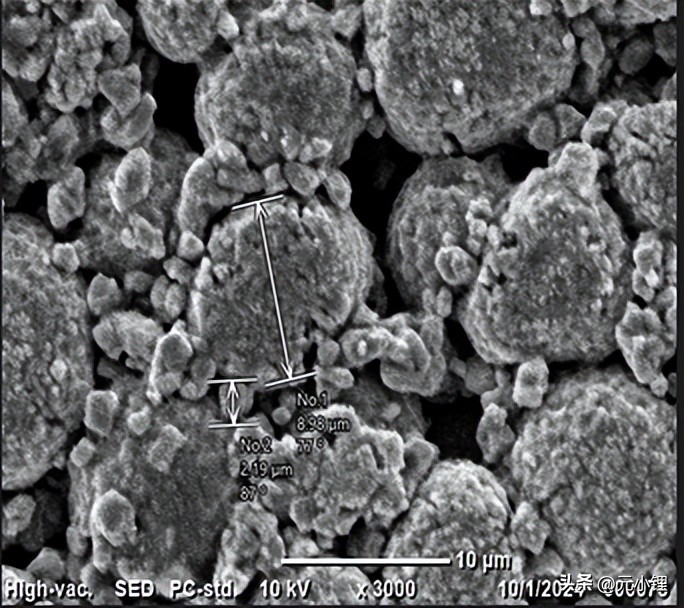

uSealing design:

1.Al tab to nickel-plated copper tab.

2.Tab width :15mm

3.Tab thickness:~150um

4.Nickel-plated copper tab.

5.Tab width :15mm

6.Tab thickness:~200um

Welding mode

Effective sealing width :2mm

Welding area :15*3mm

spacing width: ~6mm

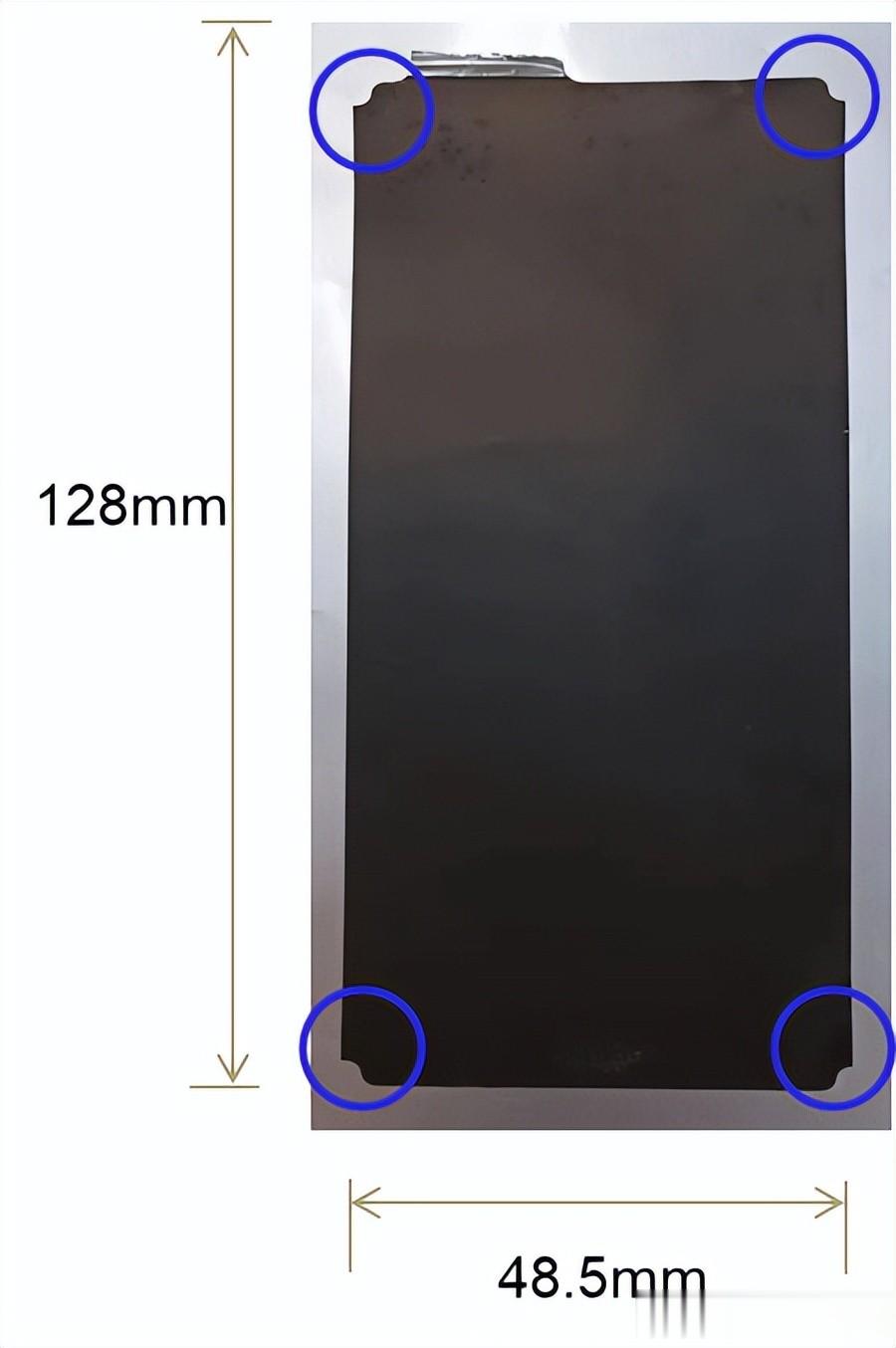

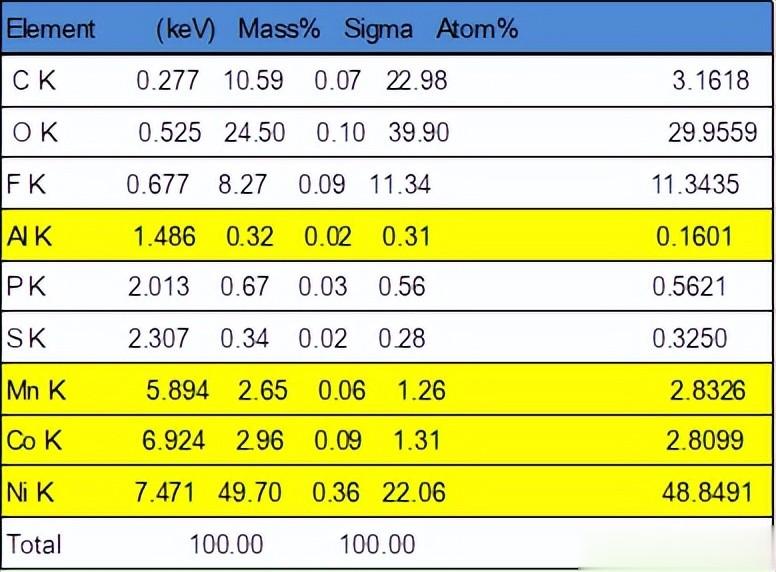

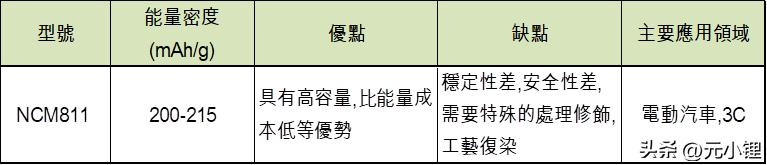

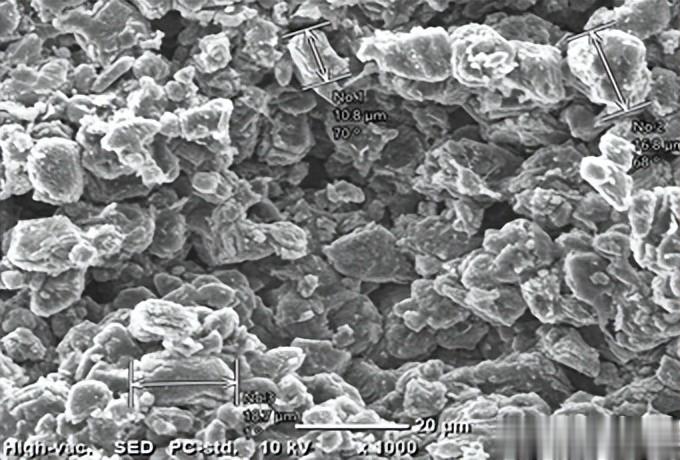

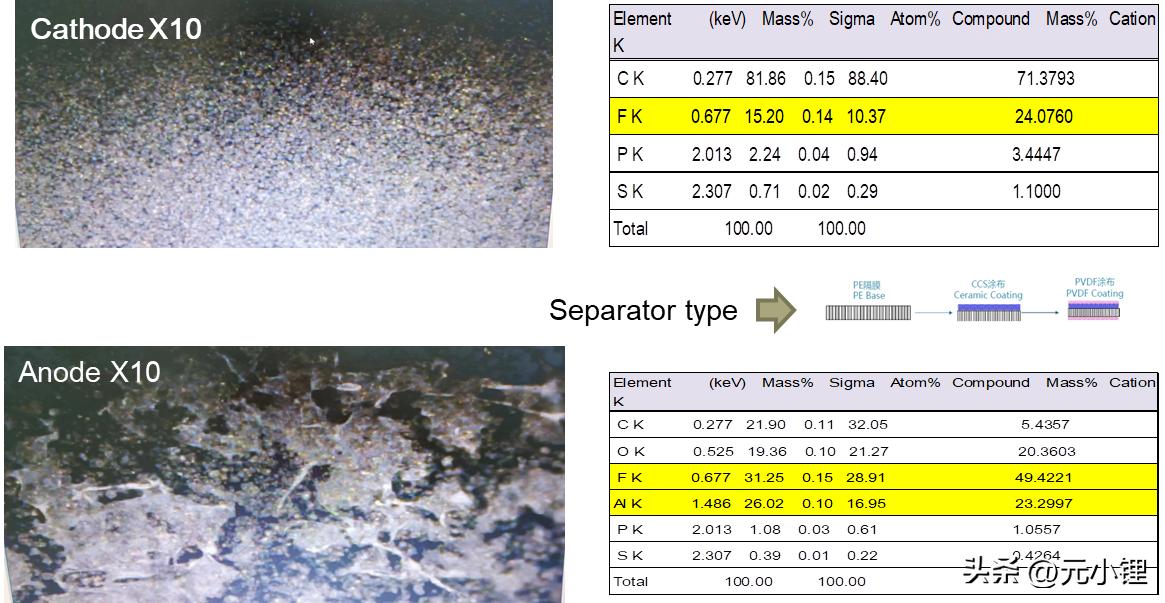

Cathode material analysis

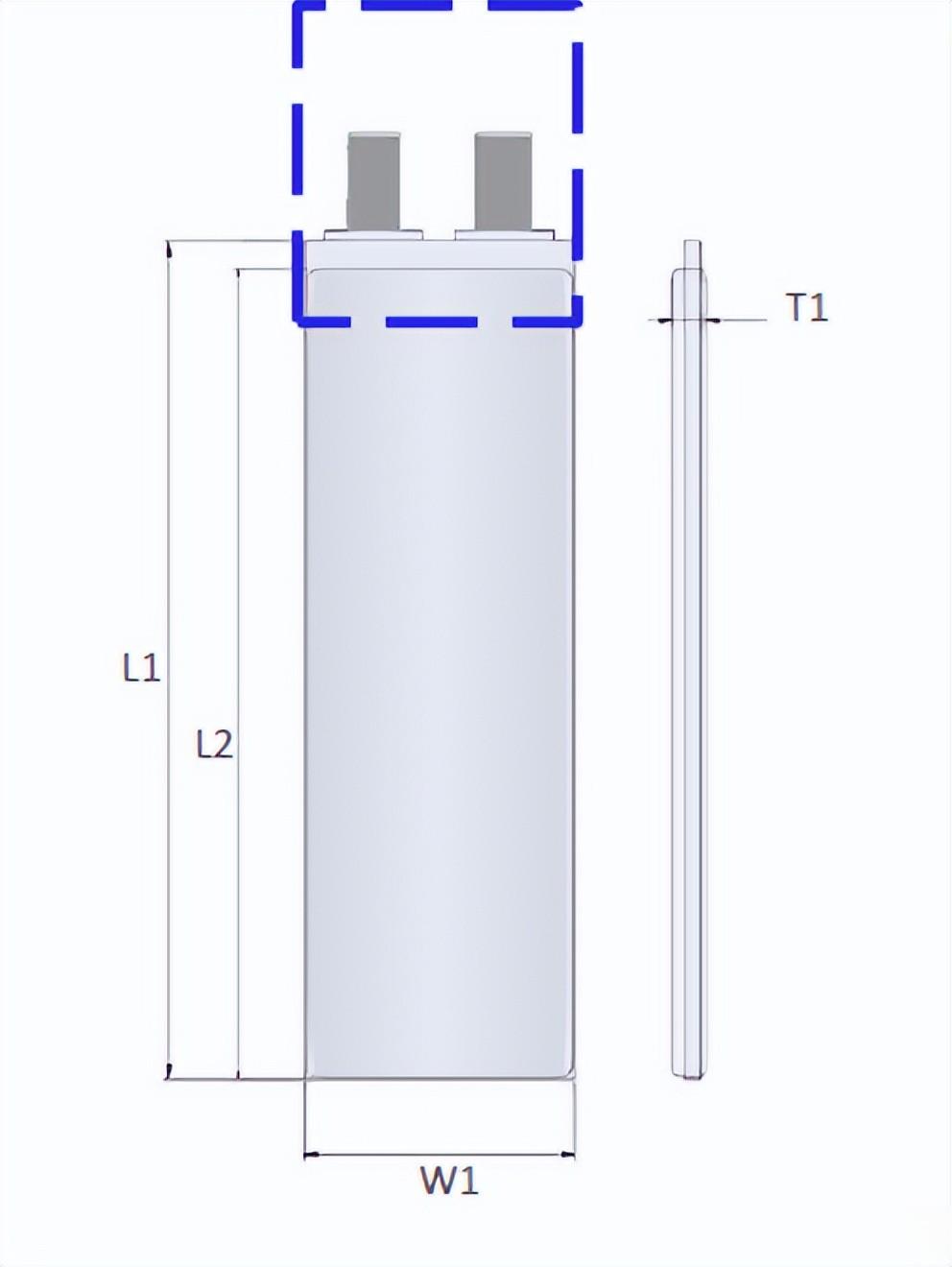

1.Electrode thickness :130um

2.Polycrystalline NMC material.

3.All four R corners are chamfered

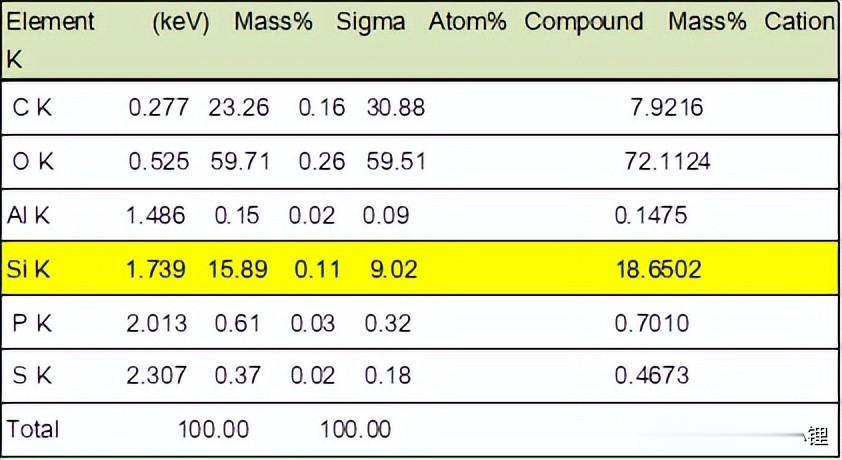

Anode material analysis

1.Electrode thickness :134um

2.Add Si material.

3.All four R corners are chamfered

碳材料与SiOx 复合的优势有:

①碳材料本身导电性很好,与SiOx复合可改善导电性;

②碳材料嵌脱锂的体积变化小(石墨约8%),与SiOx复合可减少复合电极的整体膨胀;

③碳材料可保护活性材料,避免与电解液的直接接触,并缓冲材料的体积膨胀,提升循环稳定性。

Separator coating material

Reverse calculation

1. Adopt Z-shaped stacking method.

2. All preparatory processes before stacking must be carried out in a dry environment.

3. All welding areas must be covered with PI tape insulation.

4. JR needs to be hot-pressed at high temperature first.

5. The electrolyte requires a low viscosity solvent.

6. For high Si ratio, it is necessary to pay attention to the difference in thickness after different SOC%.